As we all know, most medical supplies such as vaccines and plasma must be at precisely controlled low temperatures to ensure their effectiveness. Any temperature change beyond the standard range during the entire transportation and storage process will cause the failure of vaccines, plasma and other medical supplies, and even have a fatal impact on people.

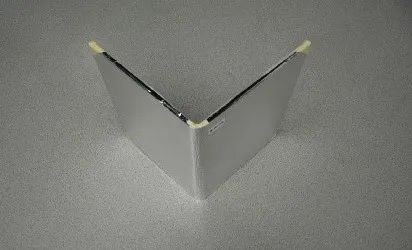

For medical insulated boxes such as medicines, biological products, blood products, diagnostic reagents, and medical equipment that require long-term temperature control for storage and transportation, it is recommended to use vacuum insulation panels as the insulation layer. The thermal conductivity of vacuum insulation panels (hereinafter referred to as VIP) is as low as below 0.0025, which is currently the most effective cold chain insulation material.

The thickness of the insulation layer of a refrigerated truck is 50 to 120 mm if polyurethane foam is used; if a vacuum insulation board is used, an insulation layer of 20 mm thickness can achieve the same insulation effect.

VIP can effectively exert its thermal insulation performance only when its vacuum degree is guaranteed. Once there is penetrating damage to the VIP membrane structure, gas leakage will occur, the vacuum degree will be reduced, and the original thermal insulation performance will be lost. Therefore, barrier film materials play a very critical role in maintaining thermal insulation performance.

Take Haotian Technology's VPU786 Insulation Cold Chain Shipping Box as example, which is a long time safe cold chain box for 2 to 8 deg C temperature controlled cooler. With high quality VPU insulation, and innovated cubic inserting ice pack to keep cooling air cycling, no leaking outside the box.The VPU786 can be achieved through the use of VIP and VPU packaging in Cold Chain Packaging and shipping process.

In the past, VIP was mainly used in military industry, shipping insulated boxes and medical insulated boxes. Now, with the reduction of core material cost and the expansion of mass production scale, VIP has been widely used in refrigerators, freezers, refrigerated trucks, cold storage, refrigerated refrigerated containers, medical medicine boxes and other fields. In addition, it has also begun to be used in aerospace, food industry and other fields.

français

français  English

English русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 magyar

magyar