The global effort to vaccinate children is complex and demands an array of supplies, including both cutting-edge products such as the latest vaccines, and items of simple technology like vaccine carriers.

Vaccines are biological products. Some lose their potency if they are not kept cool while others must not be exposed to temperatures below zero. Most of the heat-sensitive vaccines must be stored at 2oC to 8oC, and in health facilities with refrigeration capacity, doses are kept in a stationary refrigerator or a cold room until they are administered.

But often health workers bring vaccines to communities in remote villages and low-income neighbourhoods, where there are no health facilities with modern refrigeration equipment. This is when vaccine carriers become paramount. They are the final link in the vaccine cold chain.

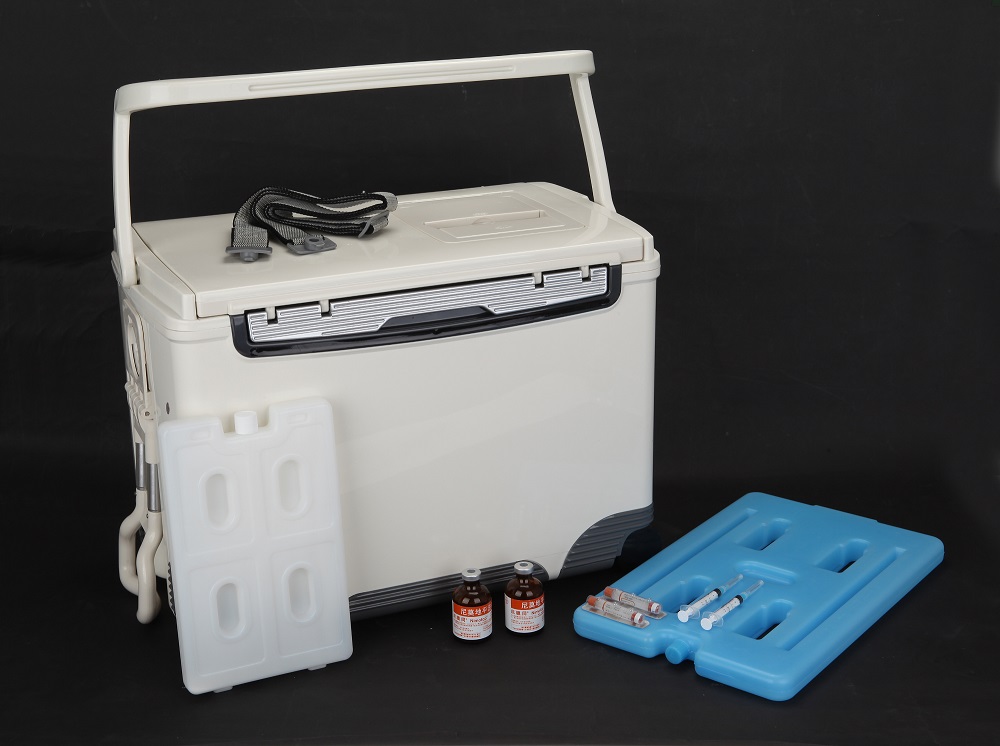

At first glance, vaccine carriers resemble picnic coolers. They are thermally insulated containers lined with coolant packs to keep vaccines cushioned and within an optimal temperature range during last-mile transportation. Depending on the type of vaccine and the size of the carrier, they can keep a vaccine cool for as long as two days.

The storage volume of vaccine carriers varies from 0.8 to 3.4 litres and the number of doses they can store depends on the type of vaccine. For example, one-litre vaccine carriers, which are the most often used in immunization campaigns, can store 700 doses of oral polio vaccines.

Vaccine carriers must be relatively light because they are usually carried by a single health worker travelling on foot, by bicycle, on small boats or other basic means to reach communities with vaccines. These journeys are frequently made on hilly pathways, narrow roads or across muddy stretches, and sometimes in temperatures above 40oC.

Despite being relatively simple in design and technology, vaccine carriers must comply with quality, safety and performance standards defined by the World Health Organization. They also need to be resistant to extreme environment conditions, including strong sunlight and heat, and to vibration, bumps and knocks.

There is continuous innovation towards more advanced models such as the freeze-preventative vaccine carriers. They have an insulated barrier separating the vaccine storage compartment from the coolant that eliminates the risk of vaccine freezing during transport. Other models still under development use an insulation barrier material or vacuum cooling technologies that allow for lighter vaccine carriers.

français

français  English

English русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 magyar

magyar